Software

RiskSpectrum RiskWatcher

Real time insights, ensuring safe and reliable operations

RiskWatcher offers instant access to projected and real time insights ensuring safe and reliable operations, providing peace of mind, and empowering you to run your business with confidence.

RiskWatcher Risk Monitor is used for monitoring online risk, simulating different scenarios and planning outages in nuclear power plants, as well as for evaluating risk exposure at offshore oil & gas installations.

RiskWatcher Trip Monitor is a tool for monitoring the risk for causing a "trip" of a nuclear reactor and for identifying equipment critical to trip. A reactor trip is the terminology used for the risk of an automatic shut-down of a nuclear power plant.

RiskWatcher is optimised to work with PSA models created using RiskSpectrum PSA.

Tune into a presentation of the latest development of RiskWatcher.

Software In Action

The RiskWatcher Dashboard

The Dashboard view is available for the Online, Planning and What-If event histories.

It gives the user an overview of the current risk levels. The cumulative risk is based on risk limitations that have been defined when equipment are out-of-service.

Different thresholds can be set and graphs will show you how much time there is left until the equipment has to be restored to service to not breach the limitations in the thresholds.

In addition, a list of equipment out-of-service ranked with priority to restore is shown as well as equipment that are of importance to keep available as to not increase the risk.

Qualitative and Quantitative Results

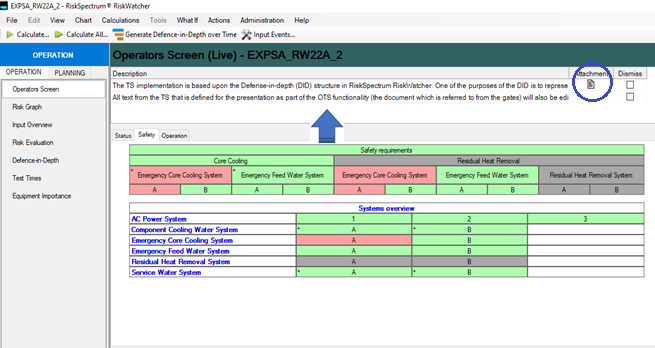

The operator screen shows a summary of the current situation with regard to quantitative risk levels as well as the compliance with technical specifications in the qualitative risk assessment shown as Defence-in-Depth.

When there are equipment out-of-service, the program calculates and display the Allowed Configuration Time.

The combination of quantitative results here shown as Core Damage frequency (CD) and Large Early Release frequency (LERF) together with the qualitative status of safety systems or safety functions compliance with operating conditions gives the user a clear picture of the current risk levels.

Quantitative Results

The logical models in RiskSpectrum PSA are used for quantifying the frequencies and probabilities of unwanted events in RiskWatcher. These are typically catastrophic events such as core damage at a nuclear power plant, explosion in a chemical plant, oil rig or refinary.

Frequencies and probabilities

The upper image shows an example of a risk display for a nuclear power station. The frequency for core damage is shown as a function of time and in a bar diagam to the right it is showing the risk level at the current time point for Core Damage and Large Early Release.

The colour bands typically indicate at what level actions are needed. Green represents an acceptable risk level, yellow an increased risk where certain measure should be taken to mitigate the risk. The orange colour band represents a level of risk that cannot be entered volontarily and the red calls for immediate shut down of the plant.

Importance Measures

The RiskWatcher interface offers also two quantitative importance measures that helps you reduce risk and anticipate and prevent events leading to non-compliant operation. This is shown in the lower picture on the right.

The Risk Increase Factor is calculated for equipment. This gives you an indication of how much the risk would increase if that equipment was found to be or was made unavailable.

The Restoration Worth Factor gives an indication of how much the risk would decrease if equipment that is unavailable was restored to service.

Qualitative Results in RiskWatcher

Qualitative results showing compliance with operating conditions or system availability gives the user a clear picture of what systems or safety functions that are available or not.

In the picture to the right you can see that the Emergency Core Cooling system has the colour red. Depending on how this system has been modelled, based on technical specification requirement or based on availability, it is considered to be in breaach of conditions for operation.

The blue arrow indicates where the program also display relevant information based on this current situation and also include a link to documents that are attached, blue circle.

RiskWatcher Connector

RiskWatcher Connector is a tool we have developed for importing data from plant information systems, such as planning tools and plant log.

RiskWatcher Connector will help you:

- Manage your plan verification by importing directly from your planning tool and use the risk monitor to demonstrate acceptable risk

- Always have up-to-date information about your current plant risk status with minimal manual input

- You can follow your risk in real time to demonstrate risk level

- Demonstrate compliance with regard to risk

RiskWatcher Trip Monitor

The RiskWatcher trip monitor allows operators to:

- Assess the online risk of reactor or turbine trip (loss of production).

- Assess the offline (planning) risk of reactor or turbine trip (for assessment of maintenance and test activities).

- Identify the critical components, or so-call Single Point Vonerability (SPV), whose single failure will lead to reactor or turbine trip

- Evaluate qualitatively the status of key system/function

- Manage and follow-up frequency of risk for trip

- Assess equipment importance based on current configuration